SS Pressure Tubing Manufacturer, SS High Pressure Tubing, Ultra High Pressure Stainless Steel Tubing, Stainless Steel 316 Pressure Tubing Manufacturer in India

Tubetec Piping Solutions is a reliable Stainless Steel Pressure Tubing Manufacturer in India. Several advantages of utilizing Stainless Steel Pressure Tube over other materials are therefore realized. Stainless Steel stands out as amongst the most rust and oxidation resistant construction materials. This property is essential for applications where SS Pressure Tube is exposed to correlation substances or conditions to reduce the service life and leaks. Stainless steel is extremely strong and imposes high pressure without failure or distortion of shape and form.

This strength enables the use of thin walls, and results in a lighter and less expensive tube and overall cost. Stainless Steel Pressure Tube is also has good qualities such as high heat resisting abilities; this feature allow the material to withstand high temperatures while its strength and other properties are not affect

Stainless Steeel Pressure Tubing Specification

| Size Range | 1/4", 5/16", 3/8", 9/16", and 1" |

| Max Pressure | 19000 |

| Dimenisons | ASTM,AISI,ASME,JIS,DIN,EN,GB,BS,SUS |

| Material | SS 304, SS 304L,SS 316,SS 316L |

| Type | As Seamless |

| Finish | SS high pressure tubes and high preesure tubing pipes can be supplied to aircraft industries |

SS Tube Supplier, High Pressure SS Tubings, Seamless High Pressure SS Tubing, Seamless SS Pressure Tubing, 304 SS Tubes, SS Pressure Tubing Manufacturer in India

Tubetec Piping Solutions is well-known Stainless Steel Pressure Tubing Manufacturer and Supplier in India. Our SS Pressure Tubing is in regular stocked sizes from 6mm to 50mm OD with 0.5mm to 10mm thickness. We supply Schedule 5, 10, 40 and 80 to ensure that the pressure necessary can be met. Made through latest technology processes such as cold drawn and extrusions, these seamless tubes are robust in construction. These Pressure Tube also undergo through adequate testing that meets the requirements of ASTM and ASME for the high pressure applications the Pressure Tube will be used in industries such as petrochemical, HVAC and power generation industries. We are also leading Stainless Steel Pipe Manufacturer in India.

Grades of Stainless Steel Pressure Tubing

Send a RFQ now and Get the Best Prices for SS Pipes and Tubes.

Stainless Steel Pressure Tubing Chemical Compositionss

| Chemical Compositions % | Cr | Ni | C | Mg | Mo | Si | P | S |

| 304 (UNS S30400) | 18.0 – 20.0 | 8.0 – 11.0 | 0.08 (max) | 2.00 | -. | 1.00 | 0.045 (max) | .030 (max) |

| 316/L (UNS S31600 / S31603) | 16.0 – 18.0 | 10.0 – 14.0 | 0.03 (max) | 2.00 | 2.0 – 3.0 | 1.00 | 0.045 (max) | .030 (max) |

| 317L (UNS S31703) | 18.0 – 20.0 | 11.0 – 15.0 | .035 (max) | 2.00 | 3.0 – 4.0 | 1.00 | 0.045 (max) | .030 (max) |

Mechanical Properties of Stainless Steel Pressure Tubing

| Material | Heat | Temperure | Tensile Strength | Yield Strength | Elongation %, Min |

| Treatment | Min. | Ksi (MPa), Min. | Ksi (MPa), Min. | ||

| º F(º C) | |||||

| TP304 | Solution | 1900 (1040) | 75(515) | 30(205) | 35 |

| TP304L | Solution | 1900 (1040) | 70(485) | 25(170) | 35 |

| TP316 | Solution | 1900(1040) | 75(515) | 30(205) | 35 |

| TP316L | Solution | 1900(1040) | 70(485) | 25(170) | 35 |

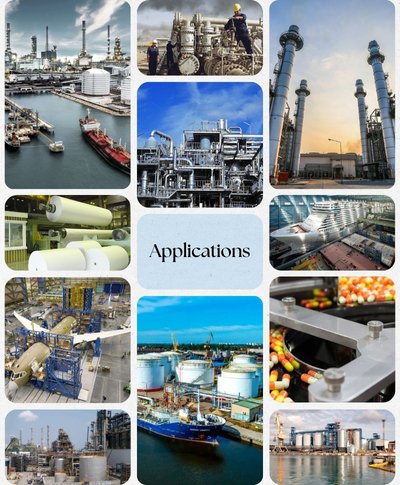

Application of Stainless Steel Pressure Tubing

-

Energy industries

-

Chemicals

-

Modern Architecture

-

Textile Machinery

-

Construction

-

Oil & Gas Industry

-

Ship Building

-

Pulp and Paper

Other Type of Stainless Steel Pressure Tubing

SS Pressure Tubing Exporter in India

*Check Out Our Stainless Steel Pressure Tubing Price in India

SS Pressure Tubing Supplier in India

*Check Out Our Stainless Steel Pressure Tubing Price in IndiaCities We Have Supplied Our Stainless Steel Pressure Tubing

- Nagpur

- Jamshedpur

- Bhavnagar

- Chandigarh

- Nashik

- Gurugram

- Ahmedabad

- Noida

- Bareilly

- Kochi

- Bharuch

- Hyderabad

- Thrissur

- Patna

- Chennai

- Indore

- Jodhpur

- Bangalore

- Prayagraj

- Visakhapatnam

- New Delhi

- Surat

- Kanpur

- Rajkot

- Aurangabad

- Gurugram

- Aligarh

- Jamnagar

- Thiruvananthapuram

- Meerut

- Bhubaneswar

- Kolkata

- Bhopal

- Lucknow

- Rourkela

- Ranchi

- Mumbai

- Ghaziabad

- Vijayawada

- Vadodara

- Faridabad

- Madurai

- Jaipur

- Coimbatore

- Trivandrum

- Mysore

- Agra

- Vapi

Countries We Have Export Our Stainless Steel Pressure Tubing

- USA

- Russia

- Australia

- Vietnam

- Brazil

- Netherlands

- Japan

- Philippines

- France

- UAE

- South Africa

- China

- Qatar

- Mexico

- Kenya

- Germany

- Bangladesh

- Algeria

- Peru

- Kuwait

- Saudi Arabia

- Kazakhstan

- Singapore

- Thailand

- Poland

- Ukraine

- Italy

- Congo

- Sri Lanka

- Venezuela

- United Kingdom

- Turkey

- Angola

- Oman

- Bahrain

- Denmark

- Indonesia

- Canada

- Egypt

- Argentina