SS Elliptical Tube Manufacturer, 316 Stainless Steel Elliptical Tubes, SS 304 Elliptical Tubes, Stainless Steel 304L Elliptical Tubes, SS 201 Elliptical Tube Manufacturer in India

Tubetec Piping Solutions is one of the biggest Stainless Steel Elliptical Tubes Manufacturer in India. Our SS Elliptical Tubes can be made from different types of stainless steel materials such as SS 304, SS 304L, SS 316, SS 316L and SS 201. Cold drawing of the SS Elliptical Tube is followed by welding after which the Tube undergo an elaborate forming process to result in the elliptical shape. The SS Elliptical Tube is subjected to heat treatments for improving its strength and following the process of heat treatment it is polished to make a bright and shiny surface. Stringent and regular quality control examinations guarantee the SS Elliptical Tube has the capacity to meet the international standards such as ASTM and ASME.

SS Elliptical Tube also avaliable in different schedules from a minimum wall thickness of 0.8 mm to a maximum of 7.0 mm outer diameter of the SS Elliptical Tube starts from 15 and goes up to 100 mm. New sizes can also be produced to correspond to certain project needs in case the required sizes do not exist, which is always a plus.

Stainless Steeel Elliptical Tube Specification

| Dimenisons | 20 mm x 10 mm – 300 mm x 125 mm (See Range Below) |

| Grades | AISI 201, 304, 316L, etc. |

| Standards | ASTM A213, ASTM A249, ASTM A269, ASTM A270, ASTM A790, ASTM A789 |

| Wall Thickness | 1.0 mm – 6.0 mm |

| Tolerance on length | Commercial Length: 6000mm +/- 30mm Fix Length: from 1200 mm up to 12000mm with a tolerance up to -0/+ 5mm |

| Finish | Seamless, Welded, Brushed, Pickled, Solution Annealed and Pickled up to O.D. 219.1mm, Polished Grit 120 – 600, Mirror Polished |

| Applications | Construction & Building, Heat Exchange, etc. |

SS Elliptical Tube Supplier, Stainless Steel 202 Elliptical Tube, SS Seamless Elliptical Tubes, SS Elliptical Tube Manufacturer in India

Tubetec Piping Solutions is well-known Stainless Steel Elliptical Tube Manufacturer and Supplier in India. The primary purpose of our company is to provide the best SS Elliptical Tubes, which is produced to match the highest level of performance and quality. As an innovative company, we supply sophisticated software tools adapted to specific industries such as architecture, automotive, and pharmaceutical industries. The vision that I would like to espouse for our company is to be amongst the absolute best providers of products and services within the market by ensuring that the products that we bring forward to the consumer are as outstanding as can be in terms of quality, while customers who engage our services should get the best experience that they could ever get and technology support that is second to none. Our primary business strategy is establishing long-term relations with customers, thereby providing consistency and success, as well as creating an association with trustworthiness, reliability and capability to succeed in the entire global market. We are also leading Stainless Steel Needle Tube Manufacturer in India.

Grades of Stainless Elliptical Steel Tube

Send a RFQ now and Get the Best Prices for SS Pipes and Tubes.

Stainless Steel Elliptical Tube Schedule Chart

| NB SIZES | SCH 5 | SCH 10 | SCH 40 | SCH 80 | SCH 160 |

|

1/8″

|

|

|

|

|

|

|

1/4″

|

|

|

|

|

|

|

3/8″

|

|

|

|

|

|

|

1/2″

|

|

|

|

|

|

|

3/4″

|

|

|

|

|

|

|

1″

|

|

|

|

|

|

|

1 1/4″

|

|

|

|

|

|

|

1 1/2″

|

|

|

|

|

|

|

2″

|

|

|

|

|

|

|

2 1/2″

|

|

|

|

|

|

|

3″

|

|

|

|

|

|

|

4″

|

|

|

|

|

|

|

5″

|

|

|

|

|

|

|

6″

|

|

|

|

|

Stainless Steel Elliptical Tube Chemical Compositions

| Grade of Material | C | Si | Mn | P | S | Ni | Cr | Mo |

| AISI 201 | ≤0.15 | ≤1.00 | 5.50~7.50 | ≤0.060 | ≤0.03 | 1.00 ~1.50 | 13.50~15.00 | \ |

| AISI 304 | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 8.00~11.00 | 18.00~20.00 | \ |

| AISI 316L | ≤0.035 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 10.00~14.00 | 16.00~18.00 | 2.00~3.00 |

Stainless Steel Elliptical Tube Mechanical Properties

| Grade of Material | Elongation (%) | Tensile Strength (Rm) N/m m³ | Yield Strength (Rp) 0.2%N/m m³ | Hardness (HV) | ||||

| AISI 201 | ≥35 | ≥515 | ≥205 | ≤200 | ||||

| AISI 304 | ≥35 | ≥515 | ≥205 | ≤200 | ||||

| AISI 316L | ≥35 | ≥485 | ≥170 | ≤200 | ||||

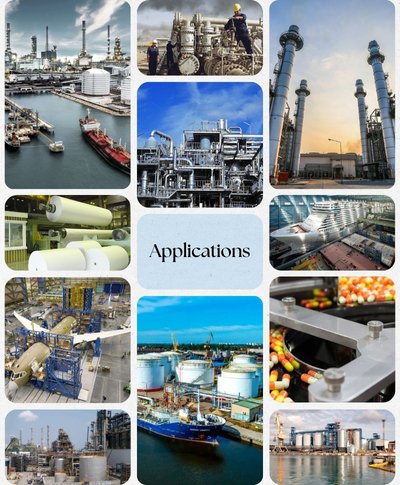

Application of Stainless Steel Elliptical Tube

-

Energy industries

-

Chemicals

-

Modern Architecture

-

Textile Machinery

-

Construction

-

Oil & Gas Industry

-

Ship Building

-

Pulp and Paper

Other Type of Stainless Steel Elliptical Tube

SS Elliptical Tube Exporter in India

*Check Out Our Stainless Steel Elliptical Tube Price in India

SS Elliptical Tube Supplier in India

*Check Out Our Stainless Steel Elliptical Tube Price in IndiaCities We Have Supplied Our Stainless Steel Elliptical Tube

- Nagpur

- Jamshedpur

- Bhavnagar

- Chandigarh

- Nashik

- Gurugram

- Ahmedabad

- Noida

- Bareilly

- Kochi

- Bharuch

- Hyderabad

- Thrissur

- Patna

- Chennai

- Indore

- Jodhpur

- Bangalore

- Prayagraj

- Visakhapatnam

- New Delhi

- Surat

- Kanpur

- Rajkot

- Aurangabad

- Gurugram

- Aligarh

- Jamnagar

- Thiruvananthapuram

- Meerut

- Bhubaneswar

- Kolkata

- Bhopal

- Lucknow

- Rourkela

- Ranchi

- Mumbai

- Ghaziabad

- Vijayawada

- Vadodara

- Faridabad

- Madurai

- Jaipur

- Coimbatore

- Trivandrum

- Mysore

- Agra

- Vapi

Countries We Have Export Our Stainless Steel Elliptical Tube

- USA

- Russia

- Australia

- Vietnam

- Brazil

- Netherlands

- Japan

- Philippines

- France

- UAE

- South Africa

- China

- Qatar

- Mexico

- Kenya

- Germany

- Bangladesh

- Algeria

- Peru

- Kuwait

- Saudi Arabia

- Kazakhstan

- Singapore

- Thailand

- Poland

- Ukraine

- Italy

- Congo

- Sri Lanka

- Venezuela

- United Kingdom

- Turkey

- Angola

- Oman

- Bahrain

- Denmark

- Indonesia

- Canada

- Egypt

- Argentina