SS Hollow Tube Manufacturer, ASTM A409 Hollow Tube, Stainless Steel Hollow Tube, Stainless Steel Hollow Tube Manufacturer in India

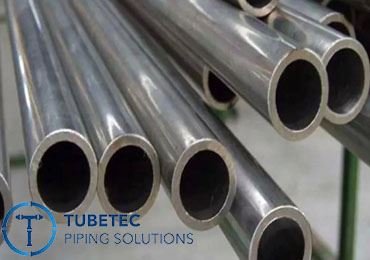

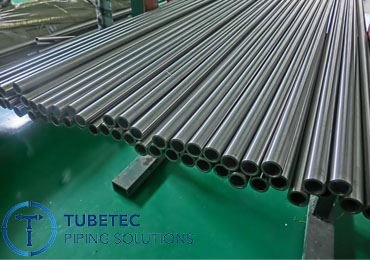

Tubetec Piping Solutions is a remarkable Stainless Steel Hollow Tubes Manufacturer in India. SS Hollow Tube have multi-purpose uses in different sectors. These materials are lightweight but tough enough to handle rolling and structural work, pipelines, and ornamental purposes. These SS Hollow Tube show very good resistance to many corrosive environments due to which they can effectively be used in chemical and marine applications. Because they are accurately dimensioned with smooth surfaces, they boost the functionality in heat exchangers, automotive parts and construction.

The goal of SS Hollow Tubes is to give Protection solution and sturdy for the construction and energy sectors. High strength, performance, and appearance make the designed gears suitable to fit international standards for various uses.

Stainless Steeel Hollow Tube Specification

| Specifications | ASTM A249 - A269 - A358 - A312 - A409 - A554 - A778 - A789 - A790 |

| Size Range | 6 mm OD to 219.1 mm OD |

| Outside Diameter | From 6mm~2500mm |

| Length | 1 Mtr Upto 32 Mtrs Long / U-Tube Length – 32 Mtrs U Tube Coil – 50 Mtrs |

| Thickness | 0.7 mm Thick To12.7 mm Thick |

| Form | Seamless, Welded, Hot Rolled, Cold Drawn |

| Shapes | Straight tube, Coil tubing |

| Ends | Plain end, Bevelled end |

| Grades | TP - 304,304L,316,316L,201 |

SS Hollow Tube Supplier, Stainless Steel Seamless Hollow Tubes, Stainless Steel 201 Hollow Tubes, SS Hollow Tube Manufacturer in India

Tubetec Piping Solutions is well-known Stainless Steel Hollow Tube Manufacturer and Supplier in India. SS Hollow Tubes avaliable in various schedules and can be used from 0.5 mm right through to 8 mm thickness and can vary in diameter from 6mm through to 200 mm and can be cut to lengths of up to 12 meters when required. Every SS Hollow Tube is thoroughly tested with the checks in dimension before piping to undergo hydrostatic pressure test and others non-destructive tests with the help of ultrasonic and eddy current test. This reaches out to mandates of ASTM and ASME professional organizations as well as upholding quality standards of individual clients. We are also leading Marine Grade Stainless Steel Tube Manufacturer in India.

Grades of Stainless Steel Hollow Tube

Send a RFQ now and Get the Best Prices for SS Pipes and Tubes.

Stainless Steel Hollow Tube Chemical Compositionss

| GRADES | UNS | C | Mn | P | S | Si | Cr | Ni | Mo |

| TP304 | S30400 | 0.08 | 2 | 0.045 | 0.03 | 1 | 18.0-20.0 | 8.0-11.0 | |

| TP304L | S30403 | 0.035 | 2 | 0.045 | 0.03 | 1 | 18.0-20.0 | 8.0-13.0 | |

| TP316 | S3160 | 0.08 | 2 | 0.045 | 0.03 | 1 | 16.0-18.0 | 11.0-14.0 | 2.0-3.0 |

| TP316L | S31603 | 0.035 | 2 | 0.045 | 0.03 | 1 | 16.0-18.0 | 10.0-14.0 | 2.0-3.0 |

Stainless Steel Hollow Tube Mechanical Properties

| Material | Heat | Temperure | Tensile Strength | Yield Strength | Elongation %, Min |

| Treatment | Min. | Ksi (MPa), Min. | Ksi (MPa), Min. | ||

| º F(º C) | |||||

| TP304 | Solution | 1900 (1040) | 75(515) | 30(205) | 35 |

| TP304L | Solution | 1900 (1040) | 70(485) | 25(170) | 35 |

| TP316 | Solution | 1900(1040) | 75(515) | 30(205) | 35 |

| TP316L | Solution | 1900(1040) | 70(485) | 25(170) | 35 |

Application of Stainless Steel Hollow Tube

-

Energy industries

-

Chemicals

-

Modern Architecture

-

Textile Machinery

-

Construction

-

Oil & Gas Industry

-

Ship Building

-

Pulp and Paper

Other Type of Stainless Steel Hollow Tube

SS Hollow Tube Exporter in India

*Check Out Our Stainless Steel Hollow Tube Price in India

SS Hollow Tube Supplier in India

*Check Out Our Stainless Steel Hollow Tube Price in IndiaCities We Have Supplied Our Stainless Steel Hollow Tube

- Mysore

- Surat

- Chennai

- Bhopal

- Faridabad

- Lucknow

- Vijayawada

- Thiruvananthapuram

- Hyderabad

- Kanpur

- Ahmedabad

- Rajkot

- Bhubaneswar

- Agra

- Jamshedpur

- Jodhpur

- Patna

- Kochi

- Nagpur

- Ranchi

- Coimbatore

- Meerut

- Indore

- Bareilly

- Chandigarh

- Bangalore

- Kolkata

- Jaipur

- Noida

- Thrissur

- Gurugram

- Rourkela

- Vadodara

- Bhavnagar

- Madurai

- Bharuch

- Ghaziabad

- Aligarh

- Vapi

- Trivandrum

- Aurangabad

- Visakhapatnam

- Mumbai

- New Delhi

- Nashik

- Jamnagar

- Prayagraj

- Vadodara

Countries We Have Export Our Stainless Steel Hollow Tube

- Kenya

- Argentina

- Saudi Arabia

- Russia

- Bangladesh

- France

- Singapore

- Algeria

- Denmark

- UAE

- Italy

- Indonesia

- Turkey

- United Kingdom

- South Africa

- Ukraine

- Brazil

- Philippines

- Peru

- Canada

- Japan

- Kuwait

- Mexico

- Thailand

- Congo

- Netherlands

- Australia

- Vietnam

- Poland

- Venezuela

- Qatar

- China

- Bahrain

- Kazakhstan

- Germany

- Egypt

- Sri Lanka

- Oman

- Japan

- USA